Separator CAD-4

Separator CAD-5

Separator CAD-7

Separator CAD-10

Separator CAD-10-01

Separator CAD-15

Separator CAD-20

Separator CAD-30

Separator CAD-40

Separator CAD-50

Separator CAD-100

Separator CAD-150

Grain loaders

|

|

|

Frequently asked questions

|

|

Useful information about aerodynamic grateless grain separator CAD

- For cleaning and calibration of what crops is CAD separator used?

- CAD separator - is a unique, effective technology of cleaning and calibration of all known types of seeds of agricultural crops, ranging from small-seed herbs to the seeds of beans and pumpkin (grain, cereal, leguminous crops, technical and oil-bearing crops and grass seed) from weed and grain impurities. Grain is not damaged and has a high degree of purification from the light, large and small weed and grain, organic, mineral and other impurities that are hard to remove.

- What is separation according to the biological value of grain?

- The separator uses innovative patented method based on principles of pneumatic automation and fluidics, which makes it possible to separate grain according to the weight, with a high accuracy. This lets CAD separator to pick out grain that was formed in the middle zone of ear (cob, head, etc.). Using for sowing seeds obtained after this selection you will annually receive a harmonious shoots, even crop ripening and its increase up to 40%. At the same time CAD separator produces clean grain, healthy seed material by effectively taking away friable and infected seeds, which lose their weight because of infection, thus reducing the sowing quality of all material. Thus, thanks to CAD machine it is possible to separate grain acoording to its biological value.

- How to increase the yield on 5-10 centners per hectare?

- Regularly conducted researches on studying the sowing and yielding qualities of winter wheat seed, as well as 10 years of work experience of CAD separators on farms indicates stable guaranteed increase of yield of up to 40% or up to 10 c/ha. Highly accurate grain separation according to the specific weight makes it possible to pick out the most biologically valuable grain, capable to give the maximum germination and energy of sprouting.Seed obtained in this way gives is guaranteed increase of yield.

- Is it possible to separate wheat from barley?

- Yes, it is job of our equipment. Graincleaning machine CAD is able to sort the mixture of wheat and barley up to 60% in one pass. The exception is if the mixture was artificially mixed.

- In what cases is the CAD separator used in cereals production?

- CAD separator is used as dissemination on cereal plants, separating cereals according to size on 9 factions, at the same time removing shorts and crumbles, giving cereal an excellent salable condition.

- What confirmes the authorship?

- The unique technology and the separator itself are protected by Ukrainian and Russian patents, as well as international applications.

- What will be the damage of grain after separation on CAD machine?

- Thanks to sieveless the system of grain separation in the air flow there is no damage of grain (according to the results of periodic researches of CAD separator in Pogorelov Institute).

- What is the power consumption?

- CAD separators have relatively low power consumption. For example, CAD-4 consumes 1,8 kW/hour and operates on 220 Volts, and the machine with maximum productivity of 150 tons/hour consumes 31 kW/hour. The advantages of this effective technology of sowing material preparation - unique energy-saving opportunities of CAD separator, which make it possible to get high quality seed material with the least expenses. Our grain separators are economical in energy consumption and provide the manufacturer an opportunity to significantly reduce and optimize technological costs.

- Is this agricultural machinery: grain machine, grain equipment, machine for seed sorting, machine for grain cleaning, equipment for grain processing, grain treatment, sorting machine, grain cleaning machine and CAD separator — all the same?

- Yes. It is all the same.

- There is a great number of various seed cleaning machines: sieves, trieurs, vibroseparators, hydroseparators, vibropneumosorting tables,photoseparators, reflective tables, friction machines, magnetic, electrical, etc., and all of them are very well advertised. How to make a choice?

- Consult our managers and dealers to get contact detailes of the farms, which work on CAD separators. After talking with them you will be able to make a conclusion.

- What is preliminary cleaning?

- Preliminary cleaning - the clearing after which the grain heap looses at least 50% of weed impurities.

- What is primary cleaing?

- After the primary grain cleaning is allowed content of impurities up to 10% (including weed up to 3%).

- Humidity of grain material that is to be cleaned- up to ... % ?

- Usually (standard machines) up to 16 % - our up to 46 %.

- Productivity at maximum humidity of grain?

- The productivity does not practically depend on humidity. Performance mainly depends on kind of quality of separation you want to get. The higher is quality, the lower is performance. If humidity increases, decreases the flowability of the material, then performance decreases proportionally.

- Levels of noise and dust in operator's zone?

- Noise level complies with requirements and standards for machines of this class. There is a certificate. On separator the dustiness is close to zero.

- Loss of grain of the main crop to waste % ?

- There is no loss !!!

- Limits of the supply voltage? Is there any stabilization of the air flow in the conditions of the floating voltage that is usual for rural substations.

- Fluctuations in electric mains should not exceed the requirements of the electric motors of АИР type. There is no need in stabilization of the air flow because the machine uses asynchronous electric motors.

- What is the degree of complexity of separator settings?

- Setting of separator is simple. Operator of average qualification easily masters separation modes depending on the task. Changing separator operation from one crop to another takes 20 min. and one operator.

- Is narrow specialization of separator possible on impoving the part of grain in higher class? Are there any experience, documents, technologies working in real conditions?

- Yes. It is possible.

- Variation of grain humidity? Does this factor affect quality of separation?

- There are no principal requirements. For example, take grain from rain and submit it together with dry grain from another pile. That means that the main requirement for humidity: submitted grain should be taken from one pile.

- What materials besides grain can be separated?

- Any friable materials, granite crumbs, crushed stone, sand, sawdust, etc.

- Does the separator separate grain mixtures?

- Separates, in 8 cases out of 10 if grain mixtures differ significantly according to the specific weight.

- Warranty period?

- Warranty service of separator is 12 months from the date of commissioning.

- Is the separator reliable?

- The lack of drive mechanisms, except standard fan, as well as replaceable items and lubrication points provide high durability and reliability in operation.

- Is it difficult to clean the separator after changing from one crop to another?

- It takes 15-20 minutes to clean the separator.

- Are there any expensive spare parts?

- No. There are no expensive spare parts.

- Where can the separator be installed?

- The separator can work independently, in combination with equipment, transporting initial material, and is installed in technological lines of post-harvest processing of grain and grain heap (grain-cleaners equipment and grain-cleaning drying complexes), as well as in warehouses in special lines in all agricultural zones. It is possible to install the separator in hangar, on a trailer of a car.

If you have not found answer to your question, we are always ready to respond in detail to any of your questions - Ask a question to SPC "Aeromeh" Ltd.

|

|

| News

|

STRENGTH AND ENERGY IN EVERY GRAIN

20 april 2020

|

|

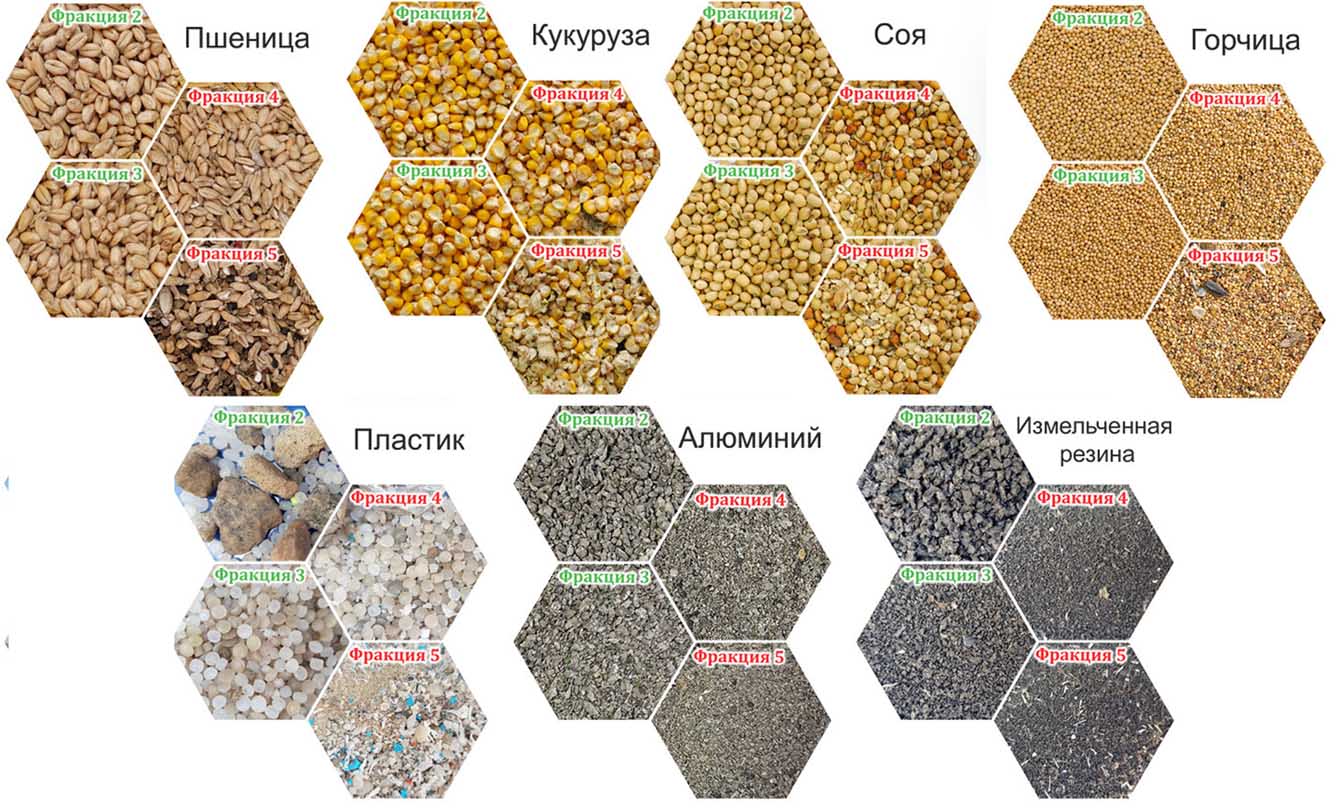

During the harvesting and preparation of grain crops for storage, it is very important to accurately complete all stages of the post-harvest process. One of the most significant steps is grain cleaning. It makes it possible to save the crop from dust and impurities, weeds, pests, dry mass, separate the seeds, and also qualitatively prepare the grain for further storage and processing. Universal grain cleaning equipment CAD separators has a high capacity, processing almost all types and varieties of crops, legumes, oilseeds, industrial, small-seed herbs and vegetables. The grain separator can be used independently or in combination with other units, performing the complete chain of processing crops. AEROMEH company offers grain cleaning machines for various tasks. From us you can buy small separators CAD-4 and CAD-5 for small farms, as well as grain separators CAD-100 and CAD-150 - more productive and always efficient. Grain cleaning equipment of AEROMEH production consists of several components. Grain enters the hopper feeder of the CAD separator. With the help of the vibrating tray, the grain is evenly distributed in the separation chamber over its entire width. Air flow generator of the CAD grain separator processes each element of the separated stream with the powerful flows. During this process, the heap is cleaned of dust, light impurities, crushed grain, weed seeds and other mineral and green impurities. Separation or sorting of grain with the CAD separator is done into 5 fractions. After cleaning with the separator CAD, the best and cleanest grain goes to the 2nd and 3rd fractions. Small impurities, crushed seeds and waste of various origins go to the 4th and 5th fractions. In the calibration mode, the 2nd and 3rd fractions of CAD separators is proper seed material, which is obtained by selecting the grain by the specific weight. The equipment has durable body, and does not have replaceable elements and lubrication points, therefore it can work for many years without failures in operation. At the peak of the season, when the grain cleaning is carried out for many hours in a row, it is very important that the machines work clearly and smoothly, because every day of a downtime can bring losses to the agricultural economy. We offer reliable equipment that does not require expensive consumables or special care, it gives maximum efficiency without taking significant investments. AeroDynamic separator CAD is a modern and reliable grain cleaning equipment. Innovative solutions used in the CAD separator allow to solve a lot of problems in the field of grain cleaning. In addition, CAD is a technology for producing high-yielding seeds. Time tested.

phones.

Administrator www.aeromeh.com

See all news

|

Marry Cristmass

20 december 2019

|

|

"Aeromeh" team wishes everyone a Happy New Year and Merry Christmas. Let your wishes come true, let your ideas successfully come true, let your aspirations and dreams lead you to new heights of happiness. Be loved in the new year and be healthy, live well and remember: we value each of you.

Read more about our location at the exhibition on our phones.

Administrator www.aeromeh.com

See all news

|

AEROMEH invites to Kiev for the international exhibition AGRO-2019

1 june 2018

|

|

From 4 to 7 June 2019 in Kiev will be held the largest international agro-industrial exhibition in Ukraine and Eastern Europe, "AGRO-2019".

AEROMECH invites you to visit our stand, which will be located near pavilion 9, place В06.

You will be able to see our equipment in operation, as well as get acquainted with the new products. You also have the opportunity to bring grain samples with you to test our grain cleaning machines at work.

We will be glad to welcome you at our stand!

Read more about our location at the exhibition on our phones.

Administrator www.aeromeh.com

See all news

|

|

Separator CAD-4

Separator CAD-4 Separator CAD-5

Separator CAD-5 Separator CAD-7

Separator CAD-7 Separator CAD-10

Separator CAD-10 Separator CAD-10-01

Separator CAD-10-01 Separator CAD-15

Separator CAD-15 Separator CAD-20

Separator CAD-20 Separator CAD-30

Separator CAD-30 Separator CAD-40

Separator CAD-40 Separator CAD-50

Separator CAD-50 Separator CAD-100

Separator CAD-100 Separator CAD-150

Separator CAD-150 Grain loaders

Grain loaders